Are you thinking green? Worried that it will “hurt” your bottom line?

If you’re in the plastics business you might want to think about putting the idea in your business model. Attached is an interesting reprint of a talk that you should read… and start thinking about how your business might PROFIT from “Going GREEN.”

Get green before it gets you, speaker advises

By Mike Verespej

CHICAGO (Nov. 20, 1:50 p.m. ET) — When it comes to doing something with sustainability and climate change, “No is not an option.”

That was the message that keynote speaker Andrew Winston, founder of Winston Eco-Strategies in Riverside, Conn., delivered at Sustain 08 in Chicago.

“It is not just an add-on to your job. It is your job,” said Winston, who urged plastics industry executives to make green thinking and sustainability a core part of their strategy instead of thinking of them as just costs.

“Apply a green lens to your business. This is happening. This is real. It is time to start moving,” he said.

The Nov. 5-7 conference was organized jointly by Plastics News and the Society of the Plastics Industry Inc.

“You have to be the brain trust on this,” he said. “You don’t want someone else to do it for you. You need to be the solution and help your customers find ways to change their carbon footprint up and down the value chain. You have to compete or you will fall behind.”

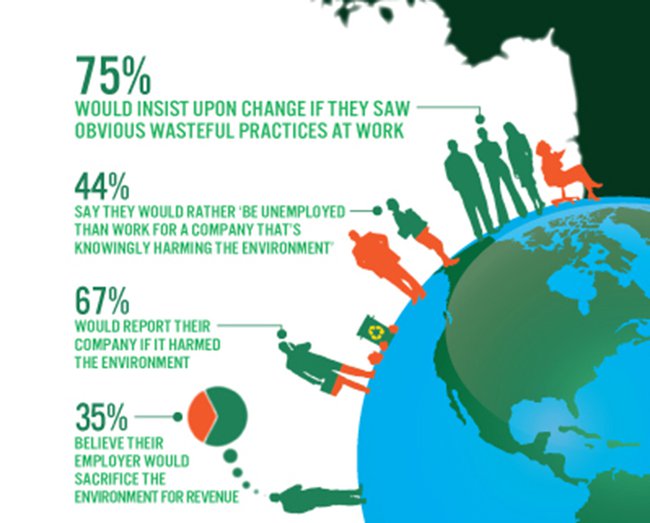

Winston told attendees to think broadly and creatively about sustainability and climate-change issues. Companies should heed the new drivers in the marketplace and changing attitudes among customers and communities, he said.

“Governments are now regulating things down to the chemical level,” said Winston, pointing to European Union regulations;, state take-back laws and bans in the United States; the Western Climate Initiative; and the growing debate on cap-and-trade programs for carbon emissions.

There is no federal action so far on climate change, but that is likely to change after President-elect Barack Obama takes office. In a taped message to a bipartisan conference on climate change Nov. 18, Obama said, “Few challenges facing America and the world are more urgent than combating climate change. Now is the time to confront this challenge once and for all.”

In addition, retailers are forcing changes, Winston said.

He noted that Wal-Mart Stores Inc. now wants a “sustainability footprint” for every product it sells and is setting standards, such as how much lead toys can contain, that are “stricter than the federal government.”

“Compliance now is compliance with your customer,” he said, pointing out how Wal-Mart told detergent makers to eliminate water from their products destined for its stores and to sell concentrates — a standard that reduced the amount of resin in such containers by 95 million pounds annually and the water in those detergents by 450 million gallons.

In addition, he said, consumers are deselecting products with a perceived, even if unproven, risk to health or the environment. For example, Winston predicts the plastic bag “will be gone globally in its present form” in 10 years.

“Feelings are facts,” Winston stressed. “It may be easier to design something out than to argue with [consumers]. You should not seek out applications where the [consumer] use is about two minutes.”

He noted there are other, more valuable opportunities that can be found to replace revenue from plastic bags.

“Instead of fighting losing battles, plastics companies should be asking themselves, “What can we do to reduce the carbon footprint and greenhouse gas emissions globally, ” said Winston. To do that well, they need to look at more than just their own products and manufacturing operations to the full value chain.

“You need to look downstream to your customers and upstream to your suppliers” to determine where the biggest impact can occur, said Winston. “You don’t want to make the wrong investments” and spend money in one area when dollars spent elsewhere can have a greater effect.

It also means thinking creatively, he said.

For example:

* Procter & Gamble Co. determined that developing a cold-water detergent would have the biggest impact on the carbon footprint of its laundry products, so it developed Tide Coldwater.

* UPS developed delivery routes for its drivers that eliminated left turns, reducing wasteful idling and cutting fuel use by 3 million gallons annually.

* Wal-Mart cut energy use in the dairy sections of its stores by 70 percent by putting doors on its refrigerated aisles. It also is using a redesigned, square plastic milk container at some of its Sam’s Club stores. The container needs only half the storage space used previously, eliminates crates and cuts transportation costs by using 60 percent fewer trucks.

“You have to learn how to make products using a lot less stuff,” Winston said, noting global competition for limited resources. China is building the equivalent of 30 midtown Manhattans each year, he said, and 30 people in India move to cities each minute, creating the equivalent of 400-500 new cities in India annually.

“The challenge for us is to provide solutions,” he said. “Five years ago, the companies leading the sustainability charge were not U.S. companies. They were in Europe because they have a much more strict regulatory environment in the European Union. They are much more aggressive about the precautionary principle and ahead of us in managing waste.”

But the payoff can be the difference between making and losing money, as well as marketplace survival. A case in point: the money DuPont Co. saved from waste reduction and keeping energy costs flat from 2003-07 equaled its net profit in that time frame, said Winston.