Last week I was reading the European Federation of Waste Management and Environmental Services (FEAD) assessment that the EU will need to invest up to $12 Billion (€10 Billion) to innovate and expand the separate collection, sorting and recycling capacity to reach the EU landfill diversion targets for plastic packaging.

I had to pause and reread the figure; $12,000,000,000??

I understand the desire to increase recycling, but at what cost do we stop pushing blindly forward and begin to compare the alternatives?

Let’s just look at the numbers:

The latest report from PlasticsEurope states that there was a total of 16.7 million tonnes of plastic packaging waste in the EU. 6.8 million tonnes of it was recycled. That leaves 9.9 million tonnes that would still need to be recycled to reach the proposed 100% recycling of plastic packaging. According to FEAD it will cost up to $12 billion to build the infrastructure to collect, sort and recycle this 9.9 million tonnes using traditional recycling methods.

This breaks down to an annual cost of $1200 per tonne to recycle this material. Even if they were to expand that expense over 10 years of recycling plastic packaging, it would still cost $120 per tonne.

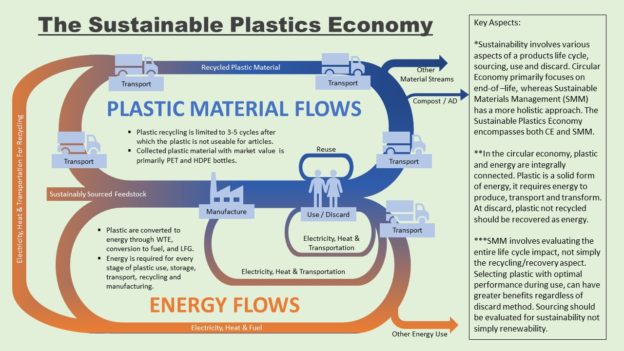

As an alternative, let’s calculate the numbers when designing plastic packaging with the existing infrastructure in mind. Most plastic packaging is discarded into a landfill. Modern technology allows for plastics to be converted into biogas within these landfills. Subsequently, the landfills are currently harnessing this biogas for auto fuel and energy. The result is recycling waste plastic by conversion to energy.

Sounds like a simple solution, but do the numbers add up?

Incorporating the technology to recycle plastics to biogas costs an average of $120 per tonne. The infrastructure and collection are already in place so there is no additional expense. The value of the biogas energy produced is $550 per tonne. This leaves a net income of $430 per tonne of plastic packaging. For 9.9 million tonnes of plastic packaging the income would be $4,300,000,000 each year. Expanding that over 10 years would be a net benefit of $43 Billion.

So, the question: Is it better to spend $12 billion for traditional recycling or earn $43 billion by combining traditional recycling with energy recycling?

(And this doesn’t even begin to address the fact that LCA analysis shows that most plastic recycling is not environmentally beneficial, nor can plastics be effectively recycled indefinitely. But, that is a subject for another article….)