Waste Expo in Las Vegas, it was an exciting week, full of education, exhibitors and auctions. The entire event was non-stop activity that left my head spinning, but there were a few interesting take-aways from the event that are definitely worth sharing.

Getting things done: (WARNING: I am starting with the “bad” part first)

It is undeniable that we need change in the way waste is handled. During the sessions there were two different approaches to affecting change.

The first approach was focused on citizen action. Honestly, I was a bit disturbed listening to Kerry Parker from the City of Alameda gloat on how they utilized local school children by organizing elementary school projects of writing letters to businesses and municipal leaders to force a straw ban and require compostable food ware. The specific comment was “we used the kids because who can say no to the children”. This seemed a bit manipulative considering that elementary children would not have the knowledge needed to understand the potential implications of material/product bans and would blindly trust the adults to have done their due diligence. (see the section below on the need for data)

On the other hand, Cheryl Coleman from the US EPA very eloquently established the need for industry collaboration, to reduce the finger pointing of blame and simply work together to create solutions. This may have been a bit of a idealistic viewpoint, but in many ways Cheryl identified a cancerous problem that needs to be addressed should we ever hope to achieve Zero Waste.

The Need for Better Data:

Kerry Parker from the City of Alameda correctly pointed out that many plastics labeled as “compostable” do not adequately biodegrade in composting and are not included in their city requirement for compostable food ware. This does not apply to all compostable plastics but is a prevalent issue with food ware. This is an issue seen in many municipalities and one which can cause significant issues with food and organics composting.

Cheryl Coleman shared that the EPA is releasing some new SMM programs later this year and is working to release facts and figures related to waste on a more regular schedule. The goal is that these additional resources will provide better tools and data to assess environmental impact for increased SMM. She also emphasized the need for product engineers to work hand-in-hand with end of life engineers when developing product and packaging designs.

It was interesting to hear the EPA emphasize that the waste hierarchy was only a guidance. Many people consider it a rule that should be followed to the “T”, but Cheryl was quick to remind that the hierarchy should provide a general direction, but one must gather the environmental impact data to determine the optimal discard method for each product. Without this full data set, we cannot understand unintended consequences and the results could be detrimental.

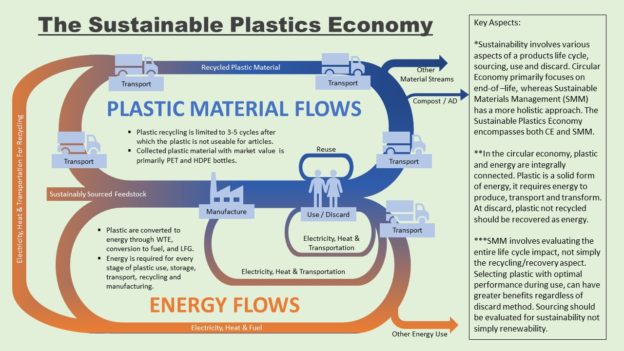

Susan Robinson from Waste Management really drove home that the devil is in the details, we cannot make sustainability related decisions without first gathering LCA data. There are some trendy phrases such as “Circular Economy” and “Zero Waste” that may sound good but they have inherent risks. We need to keep our eye on the prize. The ultimate goal is not to have a circular economy or to achieve a certain reduction in waste – the goal is to reduce our environmental impact. Every decision made needs to be assessed against the overarching and final goal of lowered environmental burdens. This was a concept echoed by several others during the conference including the US EPA and the Environmental Research and Education Foundation (EREF).

Waste Reduction is the Key:

Kerry Parker with the City of Alameda shared the efforts within the city to “unpackage” prepared restaurant food. They found that many of the local restaurants were using disposable packaging for dine-in service.

Another presenter from GARP provided case studies and examples of “alternative use” strategies. This innovative approach takes non-conforming or expired products and finds alternative uses. For example, face creams and lotions can be repackaged into leather conditioners; and brand name laundry detergents can be repackaged and re-scented to be sold as generic laundry soaps. This approach reduces waste while also increasing revenue for the manufacturing company.

One presentation that was very enlightening was Bryan Staley from the Environmental Research & Education Foundation. His presentation reviewed the 10 myths of recycling. Two of the points that really struck me were: Recycling programs can increase waste generation and that the recycling numbers reported are substantially overstated. A recent study of an office setting showed that offering paper recycling INCREASED the use of paper in the office by 82%, similarly in men’s bathrooms the recycling program increased the use of paper towels by 17%! And, because the reported numbers for recycling do not exclude the weight from contamination, the actual amount of materials recycled is expected to be nearly 30% lower than reported.

Waste is Evolving, so is Technology

Anne Johnson from the City of Alameda discussed the changing waste stream and what this means to recycling. The materials that traditionally brought value to recyclers; newspaper, glass and metal; are being replaced by light weight plastics and cardboard. The growth of plastics has a huge burden on the recycling stream as most plastics are not recyclable. This results in contamination within recycling and environmental litter creating a backlash with consumers and an inability of the waste industry to effectively manage the evolving stream.

Mike Dungan from the City of Alameda demonstrated some of the potential benefits through using pyrolysis to process mixed plastics into chemicals and fuel. This is an emerging technology, and potentially a means to extract value from mixed plastics that have entered the recycle stream.

The US EPA gently reminded that contrary to what is seen in the media, recycling is not dead. It is struggling, and we do need to rethink what and how we are recycling. The main focus should be on quality and quantity – more of the right stuff.

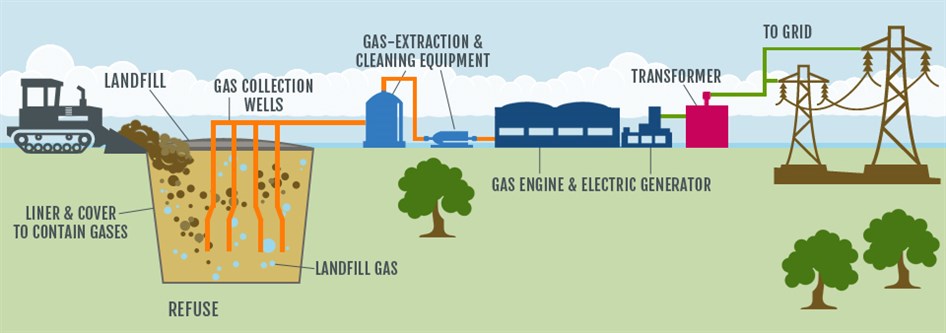

Susan Robinson from Waste Management shared some of the innovations driving sustainability at WM. One of the focal points was how WM is extracting renewable energy from their landfills – creating valuable energy from waste and reducing greenhouse gas over 80%. It was exciting to hear that WM expects to have 100% of their fleet powered by landfill gas by in the upcoming years.

Beyond 34 shared their vision of increasing the recycle rates past the current 34%. One of their primary concerns was a focus on increasing the collection rate of traditional recyclables (bottles, cans and paper) rather than increasing the types of materials collected.

And finally, the auction…

If all the information presented in the educational sessions didn’t leave you breathless, the EREF auction was sure to do the job. As the leading non-profit organization providing research and education in the waste sector, EREF was celebrating their 25th anniversary. The event was complete with a sand sculpture, vacation raffles and auctioning everything from Yetti’s, to rare bourbon and heavy equipment to golf outings. One thing you could not deny is that the waste industry is very generous in supporting EREF’s activities and efforts to create a sustainable waste management industry through scholarships, research and education.

Overall, the event was a great educational experience and one that left me confident that the waste industry is focused on sustainable practices through the use of data, LCA and collaboration. Provided we can keep our eye on the prize, the future does indeed look bright…

In medicine, there is an age-old debate surrounding whether physicians and researchers should focus on treating the symptoms of an ailment or creating a cure. From a business and shareholder perspective, treating symptoms is preferred because it ensures continued revenues and much higher shareholder return; whereas the patient would much rather obtain the cure. Unfortunately, the decision of where to spend money and marketing is most often determined by those who seek financial gain – the shareholders.

In medicine, there is an age-old debate surrounding whether physicians and researchers should focus on treating the symptoms of an ailment or creating a cure. From a business and shareholder perspective, treating symptoms is preferred because it ensures continued revenues and much higher shareholder return; whereas the patient would much rather obtain the cure. Unfortunately, the decision of where to spend money and marketing is most often determined by those who seek financial gain – the shareholders.