If asked could you provide proof that your company’s sustainability efforts are more than just greenwashing? Does your company utilize science, data and facts to drive sustainability solutions over clever marketing or “feel good” stories about sustainability?

The recent Earth Day has caused me to reflect a bit about what is actually being done to improve the environmental condition of the planet. I watched the self-promotion of companies trying to grab our attention and sell us on how sustainable and environmental they are. There seems to be a great deal of focus from companies to look at sustainability from a marketing standpoint over what should be truly sustainable or at the least better for the environment. They promote and make claims about some story or process they have implemented and claim it to be more sustainable. Unfortunately, nearly all of these companies lack the one critical component of sustainability and that is using science, data and facts to drive their solutions. It seems to me that many companies, including the big fortune 500 would have the ability and resources to hire the right people to oversee their sustainability efforts and implement solutions which are fact and data driven. Instead what is observed are companies struggling to truly understand what sustainability is about and end up implementing “feel good” or story based gimmicks to promote how sustainable they are becoming when in truth when analyzing the LCA data of these gimmicks most of these “feel good” approaches offer no environmental value or benefit at all. Do sales and marketing really have that strong of an influence over sustainability efforts which should be driven by science, facts and data?

What’s worse is when “experts” are used to push the “the only solution to plastic pollution is producing less plastic,” or “we are going to recycle our way out of this problem” agenda. It is quite unfortunate when these so called experts thoughtless and meaningless opinions are used to steer solutions to this massive problem of plastic pollution. I know of a couple of industries who are so fixated on the recycling message that the facts and data completely elude any rational thought. Anyone who understands global population and economic growth would know that producing less plastics is not in our near future and will most likely never happen without a catastrophic reduction to the human species. The planet is on a steadily increasing rate of growth which leads to more consumption and with that consumption comes the economic development of poorer nations which leads to accelerated consumption. It’s a nasty circle driven by the growth of the global population and the desire to live a more consumption based life (the good life). Regardless of whether we use plastic, paper, mushrooms, algae, space dust, or unicorn farts as our packaging materials we will always need a CRAP ton of it and will need to figure out effective, beneficial (to the environment and economy) and valuable ways of handling it. Gathering and shipping waste to other parts of the country or other countries in our globe to process isn’t the solution, nor is merely suggesting to the public to reduce plastic use.

If it’s not plastic it will be some other material we are trying to solve the pollution problem for. So easily we forget the crisis of the past. To solve the issue of paper grocery bags (which by the way was going to be the end of all the trees and human life as we knew it) we developed plastic bags which is now the new crisis and surprise! It’s also being promoted as the next cause to the end of the human race. When will the “experts,” “get it” the problem isn’t what material is being used or how much material we use, it’s what we do with and how we handle that material after use! This is always going to be the problem of a growing population. We could always go back to the days of using animal stomachs for transporting liquids but that’s a whole lot of animal stomachs and what would the vegetarians use? Companies must use packaging materials which are more intelligently designed to work within the infrastructures of our disposal environments to create a value and benefit (both environmentally and economically).

One such approach is in the conversion of plastic waste in the landfill into clean and inexpensive energy. This approach requires no special or additional handling of materials and converts plastics into biogas through the natural process of microbes. It utilizes the existing waste management infrastructures while placing the solution on materials to add value within the common disposal environment of a landfill. If all plastics were designed to work within their common disposal environment by the year 2030 (11 years) landfill gas into energy would be the single largest source of renewable energy and would surpass all other forms of renewable energy including; wind, solar, and hydro. Let’s stop the BS hyperbole that landfills are these evil and bad places or that the world is running out of landfill space. The data and the science show the environmental value and benefit of having materials convert into fuel and energy within the landfill.

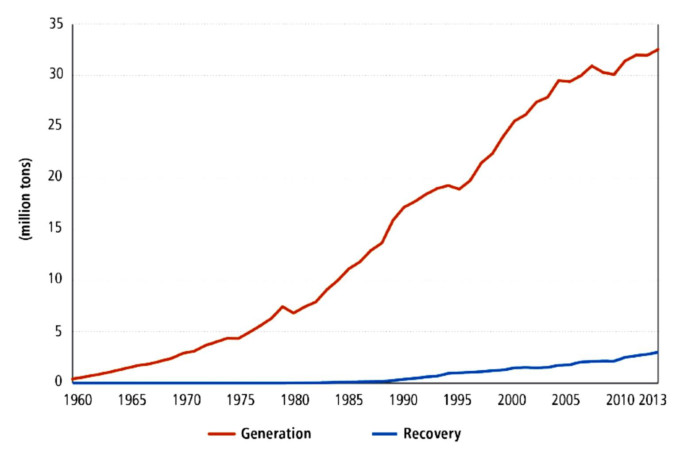

Let’s stop pretending ideas like recycling and reduction are going to solve anything. Those two words have been used as part of the “Reduce, Recycle, Reuse” campaign since the 1970’s. After nearly fifty years of that campaign look at the mess of where things are today. The recycling mess we have today certainly isn’t due to a lack of spending money or repeating the message to brain wash everyone into reducing, reusing, or recycling. It’s due to the fact that words don’t solve complex plastic pollution problems, it also shows that money doesn’t solve these problems either. Billions of dollars have been given by governments to subsidized the recycling industry to build and support it and what do we have to show for that investment? Why is the recycling industry in such a mess given all the money and investment that has been provided and why are we ok with knowing that our recycling efforts have resulted in more plastic pollution to our oceans and planet than any other activity?

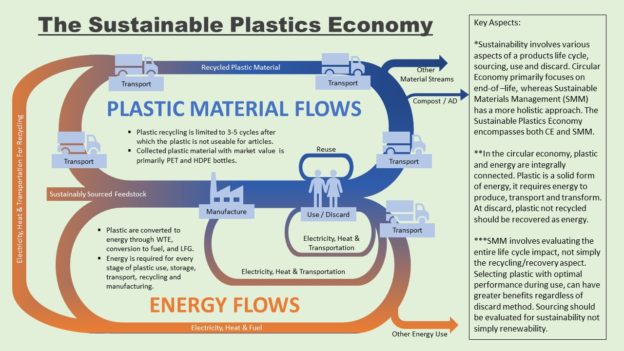

Plastics and other waste should work within their common disposal environments to have an environmental value and benefit at disposal. I know we all “feel good” about placing things in the “recycle bin” and we don’t want to know about the ugly monster of what truly goes on behind the recycle bin “curtain”. Our recycling efforts have resulted in massive amounts of plastics being dumped oceans and recycling rates in the single digits, so we can “feel good” about ourselves . It’s time we stop with the “feel good” approach and start taking action to fix the plastic pollution problem using real science, facts, and data driven solutions. Implementing solutions with the true meaning of circularity and sustainability would benefit society and the environment much more than this baseless approach of double down and continue pushing plastic recycling programs which have failed to provide environmental value (have severely polluted the planet), requires billions to subsidize and has little science and data to support that it actually has environmental value. Plastics should be designed to go away (to create environmental value) where plastics are thrown away. If one of those options should include recycling, then the science and data should support the way the infrastructures of collection, sortation, processing, and transportation are implemented in such a way that has environmental (human health is part of this) and economic value.

https://www.voanews.com/science-health/china-plastic-waste-ban-throws-global-recycling-chaos

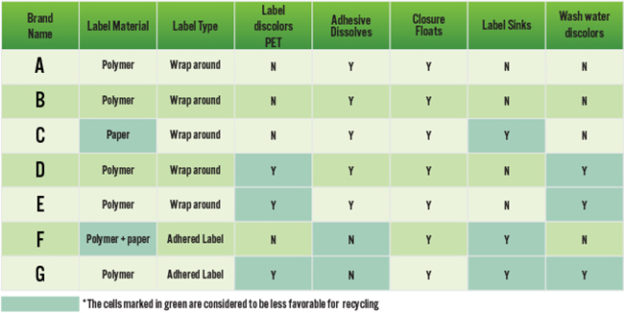

Should your company be one the many which has implemented a “sustainability” program or process with no data or science to back up the environmental claims you are engaging in nothing more than greenwashing and misleading consumers in the worse possible way. Whether your company reduces packaging, utilizes recycled content, switched to a more environmental material, implemented a bring-back recycling program, or any of many other gimmicks make sure you have the science and data to back up your claims. And I’m not talking about manipulating data to fit your program, I’m talking about letting the data drive and create your programs. 9 times out of 10 you’ll find that the data will show that your brilliant idea to implement a bring-back program or a shoe recycling program offers zero environmental value or benefit and in many cases will have a negative environmental impact requiring more resources and producing more carbon than your program thinks it is helping by figuring out how to reuse a material. The act of reusing/recycling a material/s is not inherently more environmental, it is only more environmental when it the data shows the processes involved to reuse/recycle those materials has a net environmental benefit/value.

In the end, your company’s sustainability solutions should be all about the environment; shouldn’t it?

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the