At the 2017 Waste Management Executive Sustainability Forum a message was delivered by Mr. Jim Fish, CEO of Waste Management (WM), echoing his predecessor, Mr. David Steiner. “The goal is to maximize resource value while minimizing and even eliminating environmental impact, so both our economy and our environment can thrive.” In 2016 Mr. Steiner told the National Recycling Conference in New Orleans that coupling landfill gas-to-energy with recycling would provide the “biggest bang for the buck environmentally.” Mr. Fish concurs, specifically points out that WM’s day-to-day operational technology continues to evolve and it will play an even larger role moving forward, both on the collection and disposal sides of WM’s business. And as Mr. Steiner indicated last year, what’s most exciting to Mr. Fish continues to be what’s happening with the materials that cannot be recycled or composted. “Today, environmentally safe landfills play an important role for materials that don’t have viable end markets.” Why is this? Because today’s modern landfills continue to clear all the hurdles, they work, they’re scalable, they’re economical and there are policies and regulations in place to support and encourage the developments of next generation alternatives in this space. In short, these facilities are pumping-out clean, inexpensive, renewable energy like no other option!

This is where achieving true Circularity comes into play and it’s what most technologies are striving for when it comes to last/best option in handling waste – Energy Recovery. WM spends a great deal of time and expense exploring best possible options. However, one of the major pillars of WM’s strategy is adhering to the price discipline that is Mr. Steiner’s legacy. “In a business where there is no price elasticity in demand, we must stay dedicated to that discipline” and with the current low energy prices, “nothing can compete with the low landfill pricing.” According to Mr. Fish, other options have cost-structures that are at least 3-10 times the cost of landfill air space.

WM remains dedicated to a “sustainable” recycling business. As they should, not only are they the biggest landfill company in North America, they’re also North America’s biggest recycler – by an even wider margin. In fact, it’s one of WM highest returns on invested capital, a business they want to ensure survives and thrives in the future. But Mr. Fish points out that we are in unchartered waters, the changes in products and packaging that are coming into our homes are significantly different and so are the recyclables going out, considerably increasing contamination rates and reducing value. This has led WM to take a hard look at what recycling means in term of environmental benefits.

When it comes to packaging, Mr. Fish wants us to realize that we’re an “on-the-go” society. This is translating into copious amounts of plastic packaging, much of which simply cannot be recycled. This “convenience rules” trend is going to continue, causing tension between the desire to ‘recycle it all’ and the limitations of equipment, human behavior and the customer’s tolerance for cost. With a 6-7% growth in non-recyclable flexible packaging, a 15% growth in E-Commerce and a recycling stream that’s 30% lighter than it used to be, Mr. Fish recommends evaluating the objectives to make sure we’re targeting that which achieves the greatest return value. He explains, “Environmental benefits of recycling look very different when approached from a greenhouse gas emission reduction perspective versus simply looking at how many pounds or kilograms of material are averted from landfills.” So this got Mr. Fish and the rest of WM thinking, “What‘s the right goal? Is it to keep chasing that last ton to recycle or is it to achieve the highest possible environmental benefit? For years, recycle tons has been the goal and in response to high recycling goals, we’ve seen some creative efforts to achieve these goals. Even when the environmental impacts might be questionable and the economics just made no sense. We now believe that recycling should not be the goal in and of itself, we need to be a lot more specific to ensure that we are achieving the environmental benefits we want to and think we can.”

Mr. Fish goes on to explain that when it comes to the management of organic waste (including packaging) the first priority is in trying to reduce the amount of material from making it this far down the value chain – of course. However, when this waste is collected for recovery (including non-recycled plastics, even the ones that say “recycla-bull”) it becomes feedstock for a process and a new product, either compost or an energy product. Anything not designed to comply with either option reduces the quality of this feedstock driving-up cost and threatening the entire process.

To achieve real success, Mr. Fish emphasizes the need to be actively engaged in the entire value chain of material and suggests that we make-up our minds about packaging when talking about organic waste. “Do we love it for preserving food or do we loath it for making waste? Should we ban it, tax it, recycle it, compost it, burn it or landfill it? What are the comparative environmental benefits and the costs?”

Mr. Fish went on to highlight the importance of managing food waste. The main objective here is to reduce food waste and fortunately plastic packaging plays a critical role in preserving our food. Plastic packaging is not food and it should not be expected to perform like food, which would defeat the purpose. Nor should this material be comingled with food waste disposal, elevating the risk of more waste-stream contamination. Besides, industrial composting standards (ASTM D6400) require 90% conversion to gas in 180 days, leaving no nutrient value and losing any ability to capture the gas. In my opinion, compostable standards for packaging, although well-intentioned, simply overshoot any return value. To jeopardize the entire supply chain with inadequate product performance and stability for the least common means of disposal doesn’t make much sense to me. Instead, more focus should be on the primary means of disposal (anaerobic) and the proven asset that this environment offers, the recovery of clean renewable energy.

Nonetheless, Mr. Fish emphasized that we can attack both sides of this problem. “We are in the midst of rapid change, changing demographics, changing consumer behavior, change in purchasing habits and packaging innovations, all of which are having huge impacts on recycling and the waste industry. Our response needs to be sophisticated and strategic… And as we tackle sometimes competing needs, all of us, producers, retailers, regulators and others, must use data to make the right environmental and economic decisions… We have the data, let’s put it to use!”

The data provides a clear pathway to achieving our environmental goals. Packaging should have the highest value and minimize environmental impacts in its most common discard method– without compromising the package quality. For the vast majority of packaging this does not equate to recycling, instead the environmental and economical winner is conversion to energy in modern, environmentally safe landfills. This shift in creating science and data driven solutions, rather than basing actions on perception or environmental folklore, is vital in reaching WM’s goal to process this material to its highest worth, maximizing the resource value and eliminate the environmental impacts of packaging in a way that’s both good for the economy and our planet. Although this message seemed to completely elude the panel of experts that followed, discussing the conundrums of complex packaging, I hope others will begin to take Mr. Fish’s advice before we’re all swimming in it.

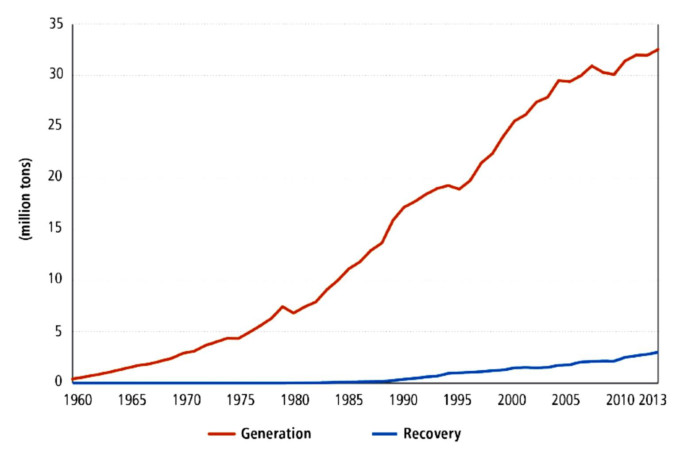

The latest estimates indicate that 8300 million metric tons (Mt) of plastics have been produced to date. As of 2015, approximately 6300 Mt of plastic waste had been generated. Despite the efforts of the last 40 years, only 9% of this material is getting recycled. The environmental impact of plastic pollution is wreaking havoc and if smarter decisions are not made regarding how this material is being managed the effects will certainly be catastrophic for the entire ecosystem.

The latest estimates indicate that 8300 million metric tons (Mt) of plastics have been produced to date. As of 2015, approximately 6300 Mt of plastic waste had been generated. Despite the efforts of the last 40 years, only 9% of this material is getting recycled. The environmental impact of plastic pollution is wreaking havoc and if smarter decisions are not made regarding how this material is being managed the effects will certainly be catastrophic for the entire ecosystem.

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the