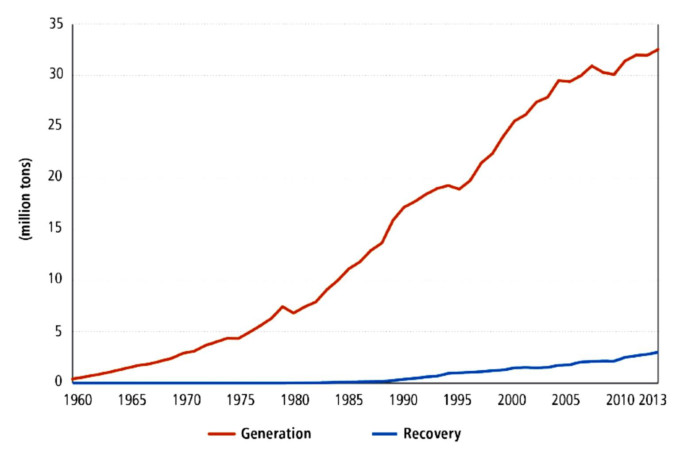

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the Association of Plastic Recyclers (APR) and the American Chemistry Council (ACC) in the 26th annual “National Post-Consumer Plastics Bottle Recycling Report.” At the current and projected rate of production, a plateau like this should ring alarm bells! The data clearly shows we are not going to recycle our way to a sustainable future.

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the Association of Plastic Recyclers (APR) and the American Chemistry Council (ACC) in the 26th annual “National Post-Consumer Plastics Bottle Recycling Report.” At the current and projected rate of production, a plateau like this should ring alarm bells! The data clearly shows we are not going to recycle our way to a sustainable future.

As someone who’s actively engaged in the sustainable management of plastics, I pay close attention to companies that are managing our waste. These companies are on the frontlines of managing the recovery and disposal of solid and hazardous waste materials, which include landfills and recycling centers. I strongly believe that integrating the advice from these groups and working with them hand-in-hand should be an integral aspect to any sustainability program.

For example, at the recent 2016 Resource Recycling Conference in New Orleans, CEO of Waste Management, David Steiner, specifically pointed out that in order to achieve the “biggest bang for the buck” environmentally, coupling recycling with landfill gas-to-energy offers the greatest return value. This is the “environmental” recommendation from David Steiner, not a shareholder perspective. And Waste Management should know, they are after all the ones actually doing all the work in collecting, processing and managing the vast majority of the our waste.

His shareholder perspective is profitability, as it should be. In a recent interview with Bloomberg, David Steiner explains that when you look at the various commodities that are recycled, there are some that are profitable. Those are primarily fiber (paper) and metals. Once you start moving into organics (plastics) and glass, they become less profitable (and in most cases over the past few years, they have lost money). In places like California they’ll do things to subsidize those types of materials to ensure Waste Management makes a profit, and then people can recycle those materials… Elsewhere, this does not work economically and understandably so. However, Waste Management will do what the municipality wants, just not at the expense of its bottom-line. They’ll be happy to recycle everything; it’s only a matter of how much you want to pay for it. But buyers beware if the commodity prices do not cover the processing costs, recycling becomes an exercise in futility.

Nonetheless, if the municipalities are willing to pay (increase taxes) for this exercise, Waste Management will be happy to oblige. They will “recycle” it, collect it, sort it and they will process it. For Waste Management, processing costs and a little profit are baked into the contract. If there’s no market, no problem for Waste Management, this material will end up disposed into a form that is not recycling.

Recently at K 2016, Patrick Thomas, chairman of the European trade group Plastics Europe, said that “every tonne of plastic that goes to landfill is a waste. It is too valuable a resource to go that way.” Really, if it needs to be subsidized by the government (tax payer money), what value is he referring to and is it sustainable?

Where exactly is the value? Last year the average bale price of recycled bottles fell by 31%, meaning that the bottles were less valuable last year than the year before. Couple this with oil prices dropping by 47% and the result is a compounded decrease in the “value” of recycled plastics.

Today, 80 million tons of non-reusable/non-recyclable plastic packaging is produced annually. This volume is expected to double in 20 years. If this 80 million tons were simply designed to comply with the primary disposal method (a.k.a. modern landfills), this material could provide enough energy to power 30 million homes for a year!

Nearly 50 years has passed since the launch of the first universal recycling symbol, today only 14% of plastic packaging is collected for recycling. When additional value losses in sorting and reprocessing are factored in, only 5% of material value is retained for a subsequent use. Meanwhile, in a business-as-usual scenario, the ocean is expected to contain one ton of plastic for every three tons of fish by 2025, and by 2050, more plastics than fish [by weight]. What are we doing?

There’s a pervasive attitude that we must recycle everything at all costs, this is not sustainable by any definition. Plastics, unlike aluminum, can only be recycled 3-4 times; eventually it will find its way into our waste streams and into our environment. Although recycling does provide us the option to extend the life of some plastics, it is not an ‘end-of-life’ solution. We cannot recycle our way out of the environmental waste problem plastics are causing. If companies continue to ignore performance compliance with todays’ primary means of disposal, facilities that actively control and convert biogas into clean alternative energy (intrinsic return value), progress will remain stagnate. The science and data validate David Steiner’s recommendation; including landfill gas-to-energy provides an environmental and economic value higher than any other option. We can take the advice or not, Waste Management will come out ahead either way, but will we?