In a recent article by Meg Wilcox, “5 sustainable packaging developments to watch in 2021” it’s a race against the clock for companies to meet their sustainability goals. This will be difficult to say the least, although the “100 percent reusable, recyclable or compostable packaging by 2025” is a catchy mantra, it is filled with empty promises and an utter lack of commonsense.

The idea that recycling is synonymous with sustainability, and recycling lobbyist calling for MORE money through EPR, is a joke. Goodrich calls it “groundbreaking”, I’m thinking more on the lines of highway robbery. The Reuse “experiment” is novel, however the scale is proportional to a freckle on an elephants ass and the core problem (EOL) is admittedly still unanswered. Plastics do not and should not end-up in an industrial compost, the infrastructure is not available and there’s NO return value. Plastics are inherently collected/managed in our Solid Waste systems, not Organic. There is no return value in making plastics Compostable. We need less rapidly biodegrading waste, not more. Making plastics perform like organic waste, defeats the purpose, and compounds the problems. This is the “unintended consequences when you switch from one system to another.”

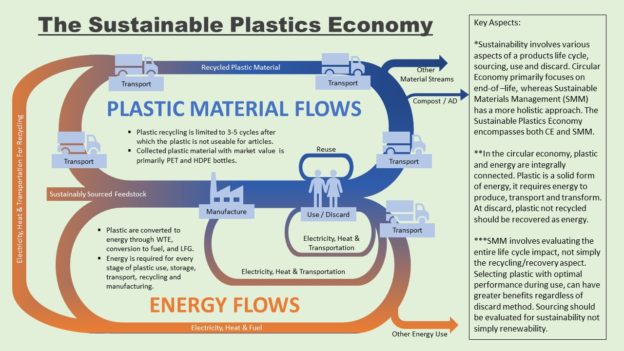

But first, let’s understand that technologies are widely available today and there are international testing standards to ensure plastics are designed to work in every MANAGED waste system we have available. Connecting these dots should be the priority of every Sustainable Packaging initiative.

Kate Daly, managing director at Closed Loop Partners states, “…more and more materials are lost to landfill that we’re not able to recapture as a valuable resource.” I would argue the reason for this is because groups like Closed Loop and SPC miserably fail to see today’s modern landfills as a valuable resource, which they have become.

It’s a shortsighted and an oddly pervasive problem in the sustainable management of plastics, a lack of knowledge pertaining to how waste is actually managed. There are several different ways plastics can be disposed after use, landfilling, recycling, incineration, and composting. The primary systems that capture the majority of discarded plastic waste are specifically designed to protect the environment and convert solid waste (carbon based) into returnable value through anaerobic bioremediation. Today’s modern landfills have emerged as a major resource for clean renewable energy (LFGE/RNG). A baseload energy resource that is providing heat for homes, fuel for vehicles and power to industries.

Sustainability managers must first and foremost understand that 90% of plastics are deposited into landfills, properly and customarily to avoid littering. Even plastics with higher recycling rates such as PET beverage bottles and HDPE bottles have a higher percentage entering the landfill than being recycled. This means every sustainability decision must provide a beneficial aspect regarding the landfilling of that plastics [ASTM D5526/D5511]. That’s sustainability through accountability, everything else is an experiment in speculation.

The “root cause” solution to plastic pollution is in making sure plastics work in today’s managed-waste systems. It seems too simplistic an answer considering the enormity of this problem. But when it’s all said and done, plastics (petroleum or plant based) must work in our managed systems, especially the one that primarily collects plastic waste – period. This is the only path to a full life-cycle and systems approach for profoundly better economic and environmental outcomes.

The “root cause” solution to plastic pollution is in making sure plastics work in today’s managed-waste systems. It seems too simplistic an answer considering the enormity of this problem. But when it’s all said and done, plastics (petroleum or plant based) must work in our managed systems, especially the one that primarily collects plastic waste – period. This is the only path to a full life-cycle and systems approach for profoundly better economic and environmental outcomes.

The latest estimates indicate that 8300 million metric tons (Mt) of plastics have been produced to date. As of 2015, approximately 6300 Mt of plastic waste had been generated. Despite the efforts of the last 40 years, only 9% of this material is getting recycled. The environmental impact of plastic pollution is wreaking havoc and if smarter decisions are not made regarding how this material is being managed the effects will certainly be catastrophic for the entire ecosystem.

The latest estimates indicate that 8300 million metric tons (Mt) of plastics have been produced to date. As of 2015, approximately 6300 Mt of plastic waste had been generated. Despite the efforts of the last 40 years, only 9% of this material is getting recycled. The environmental impact of plastic pollution is wreaking havoc and if smarter decisions are not made regarding how this material is being managed the effects will certainly be catastrophic for the entire ecosystem.