A recent blog on LinkedIn caught my eye, “9 Take-Aways That Resonated From SPC Advance.” It was about the recent SPC Advance Conference, a GreenBlue / Sustainable Packaging Coalition members only plus guests event.

“SPC Advance is an amazing opportunity to gather different members of industry, academia, and government together to share perspectives, knowledge, and insight into sustainability,” said GreenBlue and Sustainable Packaging Coalition Executive Director, Nina Goodrich.

Sounds good, right? The who’s who of professionals, the decision makers on the environment, packaging and creating a more sustainable future… Then, you hear some of the feckless rhetoric that emerges from this brain trust and it leaves you wondering if this is just an exercise in futility.

Kim Carswell of Target commented, “Bio polymers move packaging closer to petroleum independence as part of our move to a circular economy.”

Kathleen Sayler, Assistant Director of the EPA’s Office of Resource Conservation and Recovery says that currently in the U.S. over 30% of edible food goes to waste resulting in significant social, economic and environmental costs, and it is estimated that Americans waste 141 trillion calories of food annually at a cost of over $161 billion dollars. Food production accounts for 50% of land use, 80% of freshwater consumption, and 10% of total energy use in the United States.

These two need to get together for a come to Jesus moment. Land system change is a major environmental factor and our existing use in farming is already having perilous effects on our environment. Let’s not be too quick to jump into corn, sugarcane or potatoes as something that’s going to save the planet. We should not waste food and our farming should be to feed people, not our insatiable appetite for plastic, it’s not sustainable. It’s a recipe for our economy and ecosystem to go down the circular drain.

Walmart Senior Sustainability Manager, Ashley Hall, said that customers should not have to choose between products that they can afford and products that are better for them and the environment. She emphasized Walmart’s focus on selling products in recyclable packaging, and stated that the company has made packaging made with recycled content a priority.

There is no term more ambiguous than “recyclable.” Take a walk with me down Walmart’s isles and I’ll point out all the packaging that will not be recycled. Heck, we can just visit one isle; you know the one that sells all the trash bags, tinfoil and plastic utensils and foamed plates? Next time, take a look at all the Great Value brand items, along with the other brands – none of it is being recycled. Don’t even get me started on those crappy light-weighted plastic bags that have “Recyclable” on them – nonsense. We need to start basing our actions on facts and scientific data, instead of propagated myths. If you’re going to make the claim, prove its happening. It’s long overdue that we separate facts from fiction. “Recyclable” – theoretically, and that’s the problem.

Kim Carswell, Group Manager at Target stated, “Packaging is a gateway to our consumers.” She continued saying that Target likes to give consumers alternative options for the products’ and packaging’s end-of-life instead of the materials having to go to landfill, and that Target is constantly asking how its designs influence end-of-life.

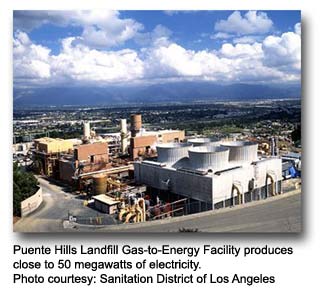

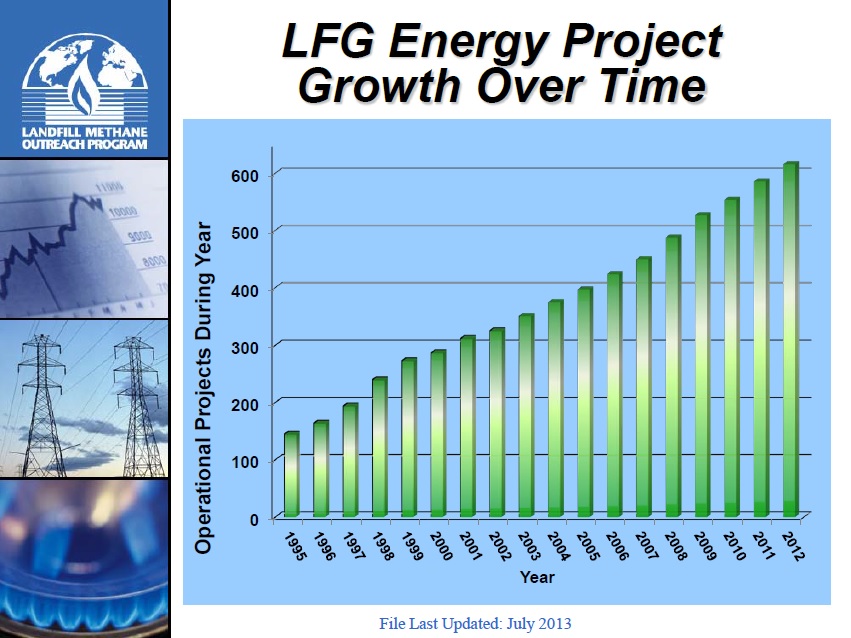

Personally, I’m not interested in trying to find a non-existent alternative option; I’m not a garbage sorter. When I buy the product, I throw away the packaging. There is nothing more counterproductive in advancing our environmental position than the demonization of landfills. Landfills are not the problem; packaging simply needs to be designed for the most common disposal method. If that’s a landfill, let’s not keep making decisions on folklore and pretending this isn’t happening. Landfill Gas to Energy is the cleanest and most inexpensive alternative energy resource available; it’s the byproduct of the biodegradation process that is coming from the natural breakdown of organic waste in this specific anaerobic environment. 80% of all municipal solid waste goes to modern landfills that control or capture this natural gas. Perhaps it would make it easier on everyone if companies like Target took genuine accountability and made all their plastic packaging Landfill Biodegradable, because it’s not getting recycled and I’m not getting in my car and taking it to my local industrial composter 80 miles away.

Amy Duquette, Sustainability Project Manager at HAVI Global Solutions, which represents the packaging department of McDonald’s, said that packaging is the consumer’s last experience with the brand, and that experience should be as positive as possible. Through mechanics such as the How2Recyle Label, brands can empower consumers to do the right thing, in this case recycle packaging.

Regulations such as Extended Producer Responsibility (EPR) are predicated on the brand/producer doing the right thing, not the consumer. The experience being created isn’t positive, it’s downright misleading! Think of all the plastic applications used at McDonald’s, the white cup, the lid, straw, utensil, packaging for utensil, condiments, all of it, IS NOT getting recycled. It’s not happening, it does not exist, stop it. EPR simply means producers will be held accountable for the post-consumer stage, not the consumer. It does not say you need to recreate a new disposal environment or champion one over the other. It starts with an easy question, where does all (minus the idiots who litter) the McDonald’s plastic applications end-up? If you said a landfill, you’re on the right track. Honesty is the best policy. Now what? That’s the path to accountability.

Al Metauro, President & CEO of Cascades Recovery, Inc. said, “Doing the same things and expecting a different outcome is insanity.” He’s absolutely right; we’ve been beating the same drum for a long time and it’s not improving our situation. These Goliaths of industry need to understand where these plastics will be disposed of and implement solutions based on that environment and, as Laura Koss, Assistant Director of the Federal Trade Commission, points out:

- Be as specific as possible.

- Make environmental claims clear and prominent.

- Don’t make qualifications about those claims only in asterisks and in tiny print.

- Be honest about what your product represents and does not represent.

- In the FTC’s eyes, it’s all about what a “reasonable consumer” might think about an on-package claim.

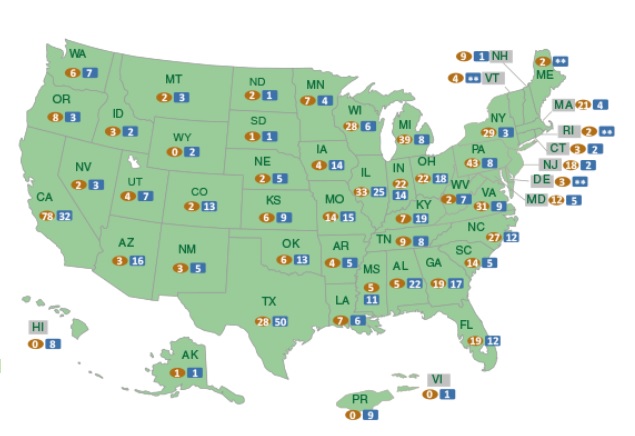

It’s absolutely unreasonable to take landfills out of the equation. Today, modern landfills are energy generating power plants and the vast majority of all of our waste ends-up in this managed and profitable environment. Let me emphasize this important and critical fact: today, nearly every State within the United States (including Alaska) already implements landfill gas to energy programs and each of these States count that energy creation as part of its green energy efforts. This is already an infrastructure that is in place and it’s a proven resource. Spinning our wheels to create more programs and new infrastructure such as for recycling, composting, incineration, etc. will bear a significant environmental and economic cost to implement.

A recent study, “Plastics: Establishing the Path to Zero Waste” provides the most comprehensive and informative look at plastic disposal today and the environmental, economic and social impact of landfilling, recycling, composting and incarnation. The only way organizations will truly reach sustainability with plastics is if they take a step back look at the entire picture and evaluate the facts.

Let’s stop promoting environmental fairytales, get the science and data to make decisions about environmental solutions that will have the greatest positive impact today and begin doing something productive. We must strongly evaluate concepts such as bioplastics, recycling and compostable plastics that have no positive impact to our environment; show me the data!!! It’s time for these Big Boys to put their big-boy pants on and take responsibility and accountability for what’s actually happening. Let’s get past trying to just make the consumer “feel good,” progress feels good.