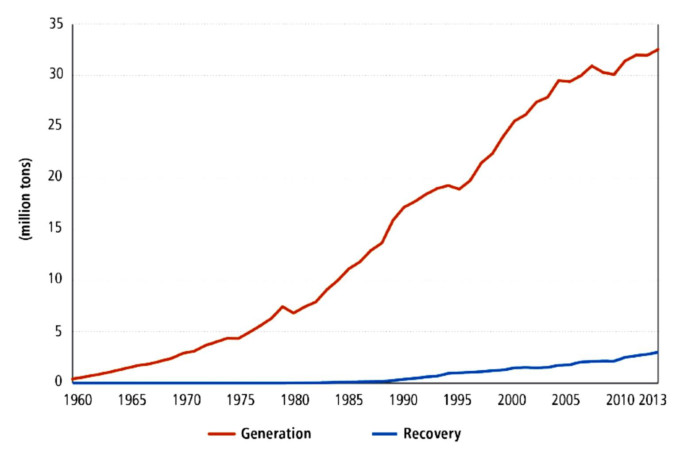

In psychology, there is a mental illness or mental disorder called Delusional Disorder. The main feature of this disorder is the presence of delusions, unshakable beliefs in something untrue or not based on reality. Over the past forty years there has been a growing increase in the feel-good result of recycling. Many sustainability managers today approach sustainability as being synonymous with recycling. The idea is that we should recycle everything no matter the economic or environmental costs. We should do it because it “feels” like the right thing to do. But none of this is based on facts, data or science. In fact, the data and science tell us otherwise and points to the dark side, that this delusional approach of “recycle everything no matter the cost” creates more environmental and economic harm than doing nothing.

Over the past forty years we have subsidized billions on top of billions of dollars, and have increased taxes (bottle bills, bag fees) to subsidize plastics recycling. The result? An industry that doesn’t and wouldn’t survive on its own, recycles less than 10% of our overall plastics and hasn’t even remotely fixed, solved, or made a dent in plastic pollution. All this time, effort and billions of dollars have not even begun to make a positive impact in the massive amounts of coffee pods, sachet packets, personal care packaging and products, zipper bags, plastic bags, plastic film, foam coffee cups, foam and plastic soda cups, lids, straws, utensils, food and product packaging, Styrofoam….. The list goes on and on, to the tune of billions upon billions of these items being disposed of each year and increasing, mind you, because we are adding more and more people to the planet and we continue to consume more and more stuff. None of the efforts that have been made thus far, or that are currently being proposed, to recycle these items have or will change the direction we have been on and are currently heading in.

When sustainability managers develop, and implement ideas and programs such as bring back programs which require additional infrastructure for managing, shipping, transportation to processors which will address less than 5% of a company’s plastic packaging and do so because it feels good or sounds good but neglects the use of facts and data to validate that the overall environmental impact is beneficial, these kinds of programs are hopeful or wishful thinking at best.

One might even ask how it’s possible to perform the responsibility of sustainability guardian’s without the use of facts, data and science? How does one solve a problem of this magnitude neglecting science and data and facts? This “feel good” approach to recycling has resulted in some people becoming mentally ill with Delusional Disorder.

So how do we begin to move in a direction to fix this mental illness? How do we open the eyes of those with Delusional Disorder and get them to start using facts, data and science to develop solutions that will have true environmental benefits and value? Delusional disorder is considered difficult to treat. Antipsychotic drugs, antidepressants and mood-stabilizing medications are frequently used to treat this mental illness and there is growing interest in psychological therapies such as psychotherapy and cognitive behavioral therapy (CBT) as a means of treatment.

These treatments would take years to get society back on track with using science, data and facts in our solutions to addressing humanities plastic waste problem. So how do we (as a society) effectively and quickly treat this widespread mental illness before it’s too late for the environment? We must begin to make reality based science and data driven decisions and develop solutions that will address the plastic waste we humans continue to produce, use and discard so that we can move in the direction of making real positive changes that will have true environmental value and benefit, instead of the delusion of acting on what might feel good but will ultimately never solve plastic pollution.

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the

The 2015 U.S. plastic bottle recycling rate posted a slight decrease of 0.6 percent compared with 2014, according to the figures released by the